Go/No-Go Gaging and Rule #1

In this Question Line Video, Brandon explains Rule #1 of GD&T (the Envelope Principle) and how Go/No-Go gages are used to verify that Rule #1 is met for a feature of size.

In this Question Line Video, Brandon explains Rule #1 of GD&T (the Envelope Principle) and how Go/No-Go gages are used to verify that Rule #1 is met for a feature of size.

As our Training Design Engineer at GD&T Basics, Jason Richter is responsible for creating and maintaining lessons and visual content for our courses and YouTube page, as well as hosting our GD&T Public Training Seminars.

In this Question Line Video, Jason discusses datum preferences for hollow cylindrical parts, where both the ID and OD of the part are mating features.

Jason discusses form controls on a per unit basis using the example of controlling flatness on a large surface in this Question Line Video.

Jason explains how to tell at a glance whether a drawing has inch or metric dimensions in this Question Line video.

In this Question Line video, Jason compares the use of functional gages and CMMs for inspection and discusses benefits and drawbacks of each.

In the Question Line Video below, Jason answers a student’s question regarding whether a feature of size can be designed to both Maximum Material Condition (MMC) and Least Material Condition (LMC) boundary constraints.

In this Question Line Video, Jason uses the example of a cylindrical datum feature to show how non-planar datums can be simulated and how they are able to constrain degrees of freedom.

“How do I inspect position if my drawing references ISO?” In today’s Question Line Video, Jason looks at a part with a cylindrical hole feature and compares the ASME and ISO standards for controlling the position of that hole.

"Why isn’t Maximum Material Condition always just the largest size the feature can be?” Jason answers our student's question and gives us a delicious way to remember the MMC state in this Question Line Video.

Is it possible to control multiple identical profiles by including a multiplier with the feature control frame? In the video below, Jason reviews a drawing with 2 irregularly shaped identical cutouts to answer this question.

In this question line video, we explain when to use the diameter symbol in a feature control frame. The examples below illustrate the unique tolerance zones shapes and sizes for position, perpendicularity, straightness, runout, and cylindricity controls.

Can you use the MMC modifier and still ensure a minimum wall thickness? To answer this question, we are going to look at a drawing of a flywheel and compare how using the MMC modifier or the LMC modifier affects the minimum wall thickness.

Why doesn't a feature of size that is indicated as a datum feature need to be located? In this article and corresponding question line video, we look at two drawing examples to illustrate why datum features are not located.

"Why doesn’t Rule #1 apply to the straightness of a Derived Median Line?" In this article, we look at both surface straightness and straightness of a feature of size to understand why Derived Median Line Straightness overrules Rule #1 of GD&T.

If I specify a hole in a practically thin feature, such as a piece of sheet metal, is this still considered a cylindrical datum? Is this a poor choice of datum? In this article, we look at an example to help us answer these questions.

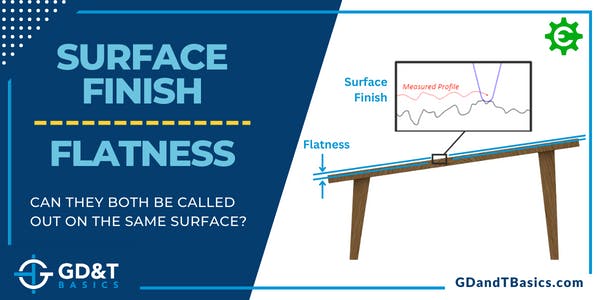

Surface finish and flatness both limit the amount of variation in a surface – one at the micro level and one at the macro level. Is it permissible to call out both on the same surface?

In our video question line, our GD&T instructors answer questions submitted by our students. In this video, we answer the question, “Is the Virtual Condition the same as the Tolerance Zone?”