When Should I Use Basic Dimensions?

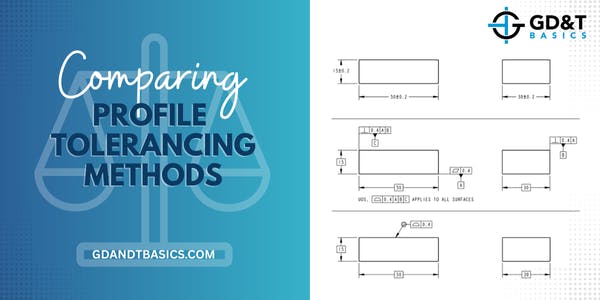

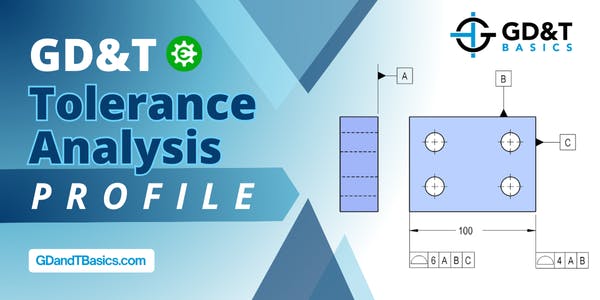

In this Question Line video, Jason demonstrates how basic dimensions paired with profile of a surface create clearer, more functional surface control.

Articles related to design concepts or application of GD&T to engineering prints

In this Question Line video, Jason demonstrates how basic dimensions paired with profile of a surface create clearer, more functional surface control.

In this Question Line video, Jason breaks down what the MMC modifier does, how bonus tolerance works, and why there is minimal benefit of applying MMC on a threaded hole.

In this video, Jason walks through several examples to explain the various ways chamfers, edge breaks, and countersinks are dimensioned on a drawing and explains what tolerances apply under the ASME standards when none are specified in the field of view.

In this design review, Jason examines the application of GD&T and tolerancing strategy for the Ambifacient Lunar Waneshaft used in the Turboencabulator, focusing on functional intent, manufacturability, and inspection considerations.

In this Question Line video, Jason discusses two possible ways to control true position for an interrupted hole scenario, discussing UAME and Virtual Condition.

In this video, Jason reviews a bad drawing, walking through each error and explaining why it violates the rules of ASME Y14.5.

In this Question Line video, Jason explains how to properly dimension the usable depth of an internal thread and reviews methods for checking it on a part.

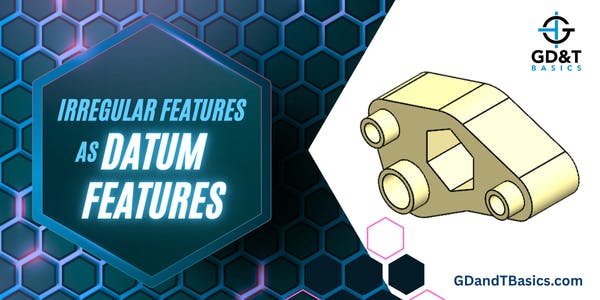

In this Question Line video, Jason explains why and how to use multiple features on a part to create one singular datum.

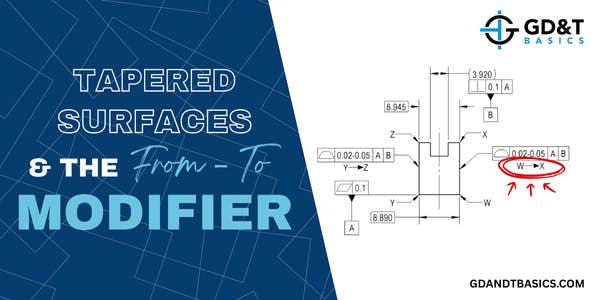

In this Question Line video, Jason demonstrates how the from-to modifier can be applied to create a wedge-shaped tolerance zone for tapered surfaces.

In this Question Line video, Jason reviews a simple part assembly to show how geometry and form factor into the tolerance stack-up analysis.

In this Question Line video, Jason reviews a submitted drawing toleranced three different ways and explains which option he would recommend.

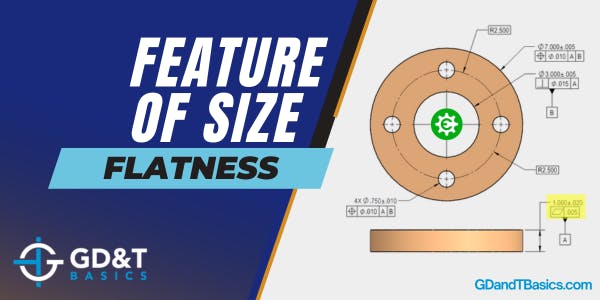

In this Question Line video, Jason reviews a submitted drawing, explaining the difference between flatness and parallelism, and gives options on how to tolerance the drawing based on what is critical to the design.

In this Question Line video, Jason reviews a submitted weldment drawing and demonstrates how to calculate the position tolerance needed for a zero-clearance fit in the worst-case assembly scenario, ensuring that the shaft can pass through two coaxial holes.

In this Question Line video, Jason explains how an irregular feature like a hexagon can serve as a primary datum feature and discusses how this part could be inspected – touching on gage design for manual inspection and point cloud analysis using a CMM.

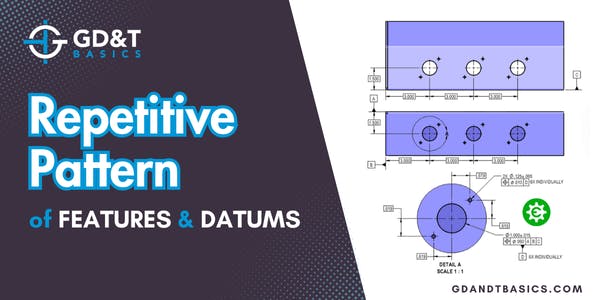

In this Question Line video, Jason discusses how to control a repetitive pattern of features with respect to a more central datum by using a “#X INDIVIDUALLY” note in conjunction with a datum feature.

In this Question Line Video, Jason walks through a submitted drawing and clarifies how the feature control frames define the location and orientation of the tolerance zones for the profile of a surface control.

In this Question Line video, Jason reviews a submitted drawing that attempts to locate two parts relative to each other and explains how to choose the correct GD&T tolerances to support the intended function.

In this Question Line video, Jason compares flatness directly applied to a surface associated with a feature of size against flatness applied to a feature of size.