Category: Inspection of GD&T

Articles related to inspection of engineering prints and interpretation of GD&T for inspection purposes

In this Question Line video, Jason explains surface vs. axis interpretation for positional tolerance at MMC and why ASME Y14.5 states to follow the surface interpretation when extreme form error is present.

In this Question Line video, learn how threaded hole location gauges are used to inspect the pitch cylinder axis and why the projected tolerance zone modifier is often the most functional spec on an internal threaded feature.

In this Question Line video, Jason reviews a drawing of a clevis bracket to show the potential effects of rounding basic dimensions.

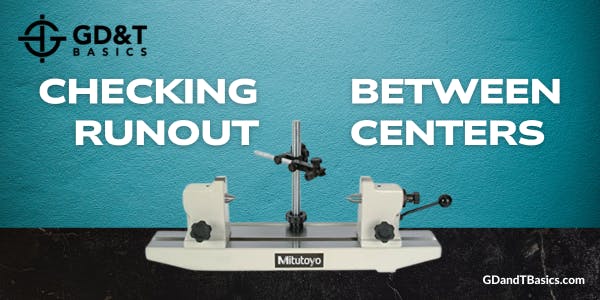

In this Question Line video, Jason walks through how to use different tools and setups to inspect the runout between centers for a submitted part drawing.

In this Question Line video, Jason shares some quick sanity checks that can help identify manufacturing issues for an extruded part being controlled by profile of a line tolerances.

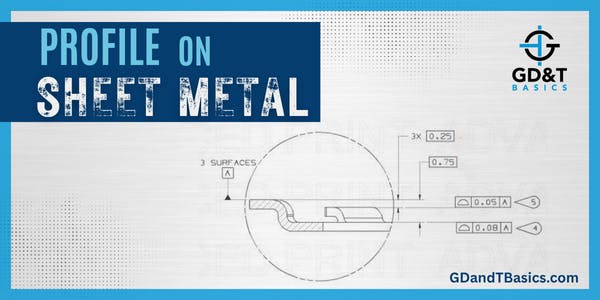

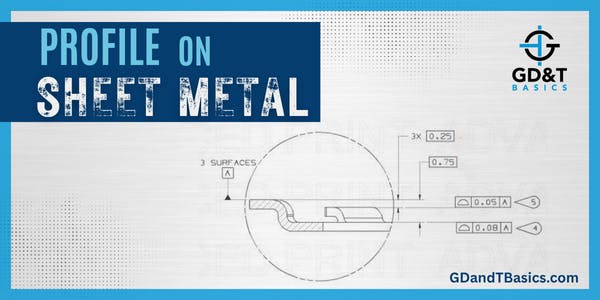

In this Question Line video, Jason answers a question regarding how to report form variation on a part made from sheet metal.

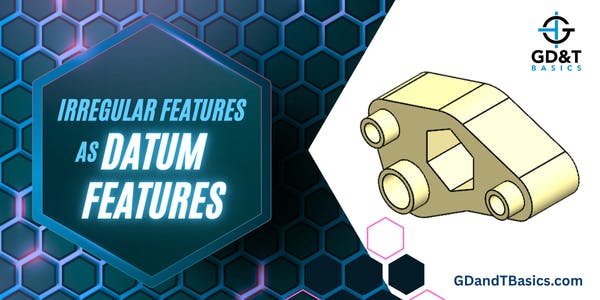

In this Question Line video, Jason explains how an irregular feature like a hexagon can serve as a primary datum feature and discusses how this part could be inspected – touching on gage design for manual inspection and point cloud analysis using a CMM.

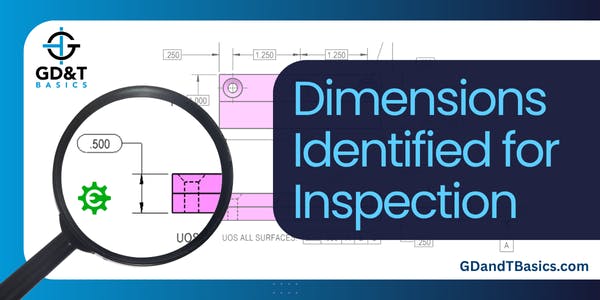

What does it mean when a dimension is circled on a drawing—and how does it impact manufacturing? In this video, Jason explains the informal use of ovals as quality control symbols and what it means for how parts are made and inspected.

In this video, Jason explains when simultaneous requirements apply and how the “separate requirements” note affects inspection, sharing examples that illustrate reasons for using each approach.

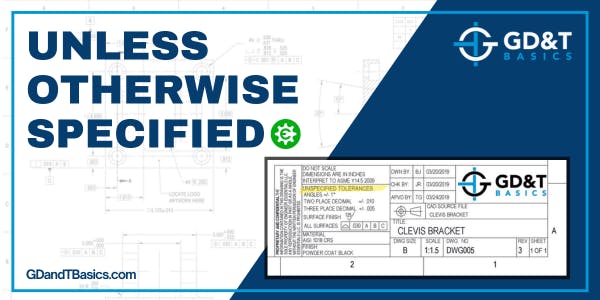

In this Question Line video, Jason answers the questions regarding the use of the Unless Otherwise Specified (UOS) statement on a drawing.

In this Question Line video, Jason discusses the role of significant figures in identifying tolerances for dimensions with unspecified tolerances. He also walks through an example of how to determine the required accuracy of the measurement equipment according to the ASME Y14.43 standard.

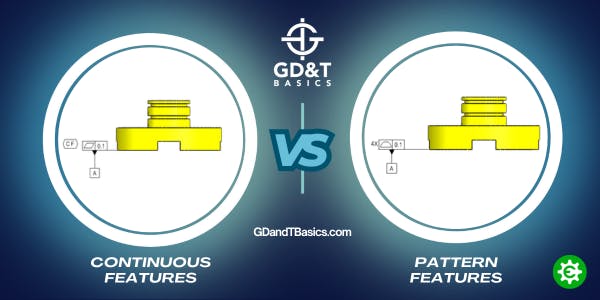

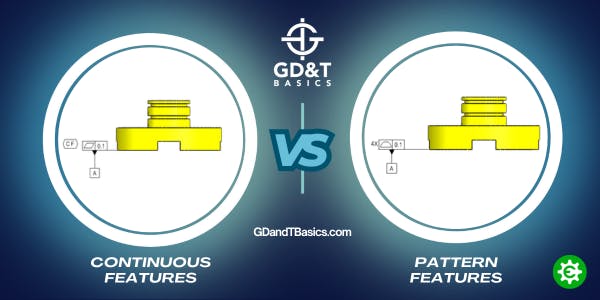

In this Question Line video, Jason compares two similar part drawings - one containing the Continuous Feature symbol and the other having a simultaneous requirement for a pattern of features - and discusses how the inspected values would be reported.

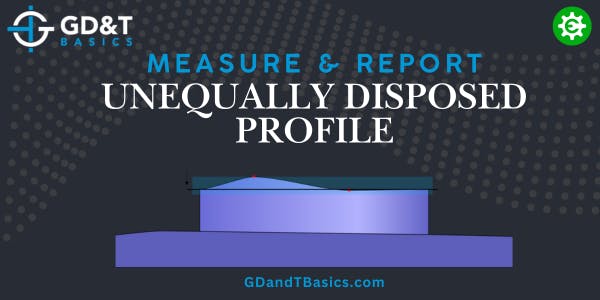

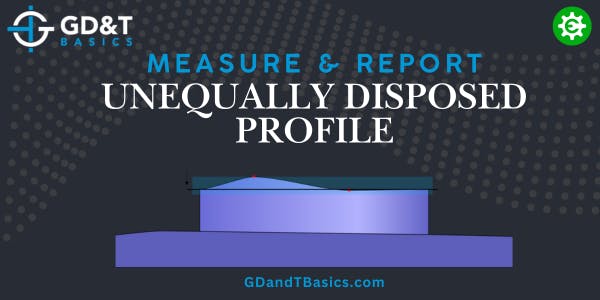

In this Question Line video, Jason explains how to measure and report the total profile deviation for an unequally disposed profile control.

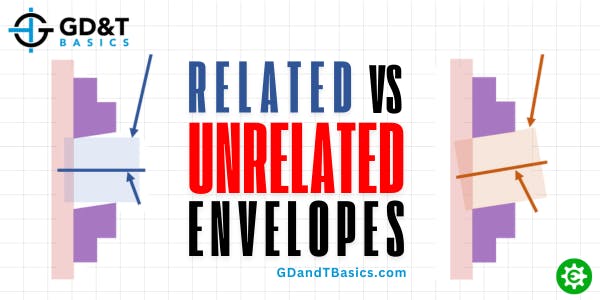

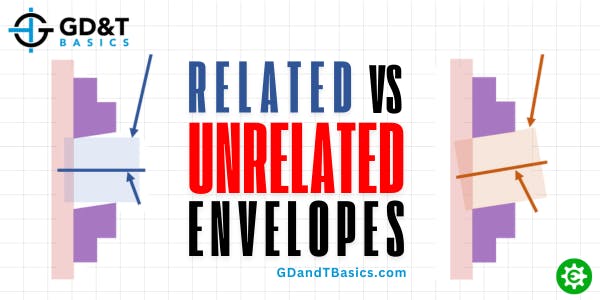

In this Question Line video, Jason explains the difference between the related and unrelated actual mating envelope and walks through an example drawing to explain when and how they are used to inspect a feature.

In this Question Line video, Jason walks through a few examples to show us the difference between profile of a surface with and without datums referenced in the feature control frame and how that affects the reported deviation.

In this Question Line video, Jason discusses a user submitted drawing, explaining options for controlling profile of a pattern of surfaces.

In this Question Line video, Jason discusses a drawing that has a tight tolerance on the location of two holes that relate back to datum features that have much larger form control tolerances.

In this Question Line video, Jason explains how datums are qualified and the difference between how CMMs and physical datum simulators set up the datum reference frame for a manufactured part.