How to Dimension the Depth of Threads

In this Question Line video, Jason explains how to properly dimension the usable depth of an internal thread and reviews methods for checking it on a part.

In this Question Line video, Jason explains how to properly dimension the usable depth of an internal thread and reviews methods for checking it on a part.

In this Question Line video, Jason walks through how to use different tools and setups to inspect the runout between centers for a submitted part drawing.

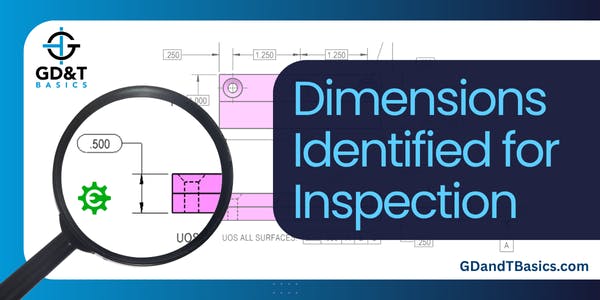

What does it mean when a dimension is circled on a drawing—and how does it impact manufacturing? In this video, Jason explains the informal use of ovals as quality control symbols and what it means for how parts are made and inspected.

In this Question Line video, Jason answers a question about reverse inspection of orientation and walks through an example to explain why you should not deviate from the inspection criteria given in the feature control frame.

In this Question Line Video, Jason gives a high-level overview of how polar probes and TIR checkers are used to inspect circularity or cylindricity.

The manufacturing industry is facing a workforce shortage, resulting in a loss of tribal knowledge and a widening skills gap. Discover how manufacturers are addressing this through employee training programs - and how GD&T Basics can help your team gain a comprehensive understanding of how to accurately interpret and analyze engineering prints, ensure compliance with industry drawing standards, and acquire the skills needed for effective inspection practices.