Coordinate Measuring Machines (CMMs) are essential tools for obtaining precise measurements. However, to ensure accurate measurements, it is crucial to understand how to use them correctly. In the video below, Jason explains the importance of recognizing and utilizing appropriate vectors when inspecting a profile or irregular surface with a CMM probe.

A Coordinate Measuring Machine (CMM) utilizes a probe with a spherical ball tip to measure points on a surface. When the probe contacts the surface, the CMM records the center position of the probe. To accurately calculate the surface location, the CMM compensates for the probe’s radius by offsetting it in a specific direction. This allows for precise determination of the actual surface position during calculations.

To calculate the correct surface position, the CMM needs to offset the position measurement in the correct direction. The CMM will offset the measurement based on the direction that the probe is traveling in. Therefore, to obtain correct measurements, the CMM probe must approach the surface along the normal vector of that surface element. In other words, the CMM probe must travel perpendicularly toward the surface element being measured.

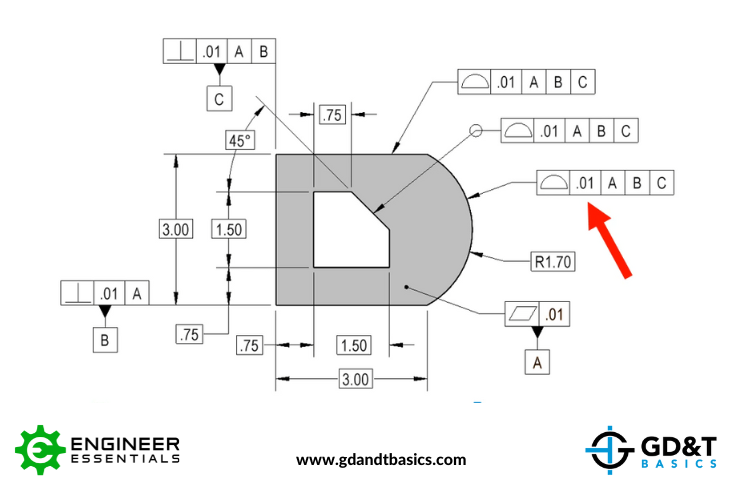

Let’s look at an example. In the drawing below, we have a curved surface (indicated by the red arrow) that is controlled by profile of a surface with a tolerance of .01. We will use a CMM to probe the surface to calculate the surface location.

The examples below illustrate the curved surface and the normal vector of a surface element. In the example on the left, the probe is approaching the surface element laterally. In the example on the right, the probe is approaching the surface element along the normal vector to that element.

When the probe makes contact with the surface, the CMM takes the location of the center of spherical tip and offsets that measurement by the radius of the tip in the direction of travel. The location of this calculated measurement is indicated by the red dot on the probe tip in the examples below. As you can see, the probe that approaches the surface laterally will record an incorrect surface measurement, whereas the probe that approaches along the vector will result record the correct location of the surface element.

In conclusion, utilizing appropriate vectors when inspecting profiles or irregular surfaces with a Coordinate Measuring Machine (CMM) probe is essential for obtaining accurate measurements. Understanding the importance of approaching the surface along the normal vector of the surface element being measured is crucial in ensuring precise calculations. Jason’s explanation in the video highlights the significance of this technique in achieving reliable results when using a CMM for measurement tasks.

Overwhelmed by the Complexity of GD&T?

Learn GD&T at your own pace and apply it with confidence in the real world.

Get Your GD&T Training