Chamfers, rounds, fillets, and “break edges” are edge features that you may commonly see on your part drawings. They are used for a variety of reasons, which typically include: part strength, burr removal, ease of assembly, and aesthetics.

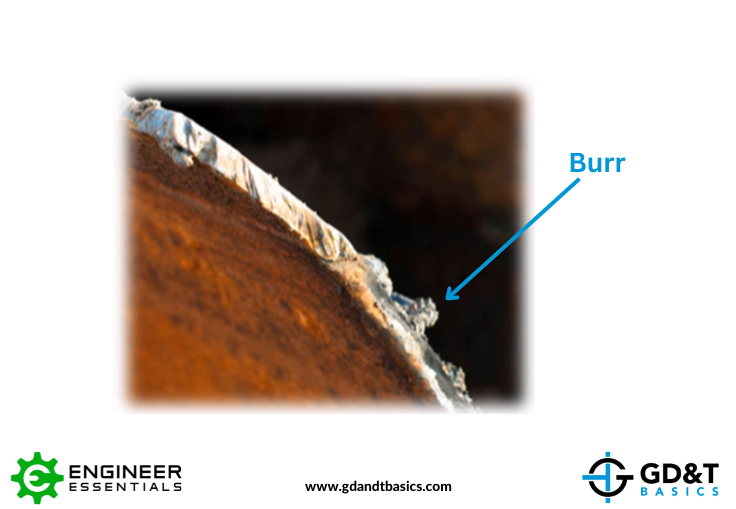

“Break all sharp edges and remove all burrs,” is a common drawing note used to notify the manufacturer that the sharp edges and burrs produced by the manufacturing process must be removed from the part. A burr is displaced material, typically generated through machining, that hangs on to the finished part. Burrs and sharp edges can cause issues for packaging, handing, and assembly, and can be a safety hazard. It is important to remove these sharp edges from our parts; therefore, this note will be seen on most drawings.

Figure 1: Example of a Burr on the Edge of a Part

Application:

You may indicate to break a specific edge by adding a note with a leader line pointing to the edge that you want broken. However, to require all sharp edges and burrs to be removed from your part, you would add a note to your drawing like the one shown in Figure 2.

Figure 2: Drawing Note for Removing Sharp Edges and Burrs

To “break edges,” material is usually removed in the form of a chamfer or edge radius (round). You would use the break edges note, rather than dimensioning a chamfer or radius, when you simply require the removal of sharp edges and are less concerned with the size of the edge features.

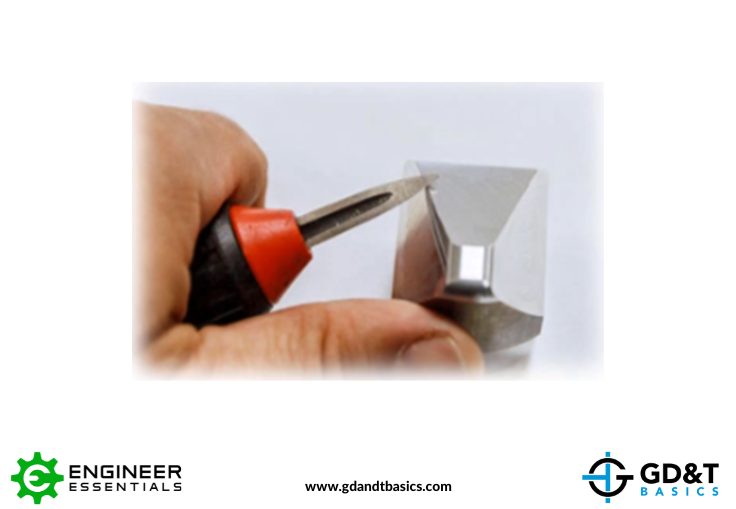

As for burrs, deburring can be done using a variety of techniques. Deburring tools can be used to remove burrs by hand, but this can also be done by the machinist in either the programming or by running additional passes using the machining tools. Deburring can also be done by sanding, tumbling, and using specialized machinery.

Figure 3: Removing Burrs by Handing using Deburring Tool

For more information regarding the “Break Edges” note, check out this video below:

Overwhelmed by the Complexity of GD&T?

Learn GD&T at your own pace and apply it with confidence in the real world.

Get Your GD&T Training