Considering Form in Tolerance Stack-Up

In this Question Line video, Jason reviews a simple part assembly to show how geometry and form factor into the tolerance stack-up analysis.

In this Question Line video, Jason reviews a simple part assembly to show how geometry and form factor into the tolerance stack-up analysis.

In this Question Line video, Jason reviews a submitted drawing toleranced three different ways and explains which option he would recommend.

In this Question Line video, Jason reviews a submitted drawing, explaining the difference between flatness and parallelism, and gives options on how to tolerance the drawing based on what is critical to the design.

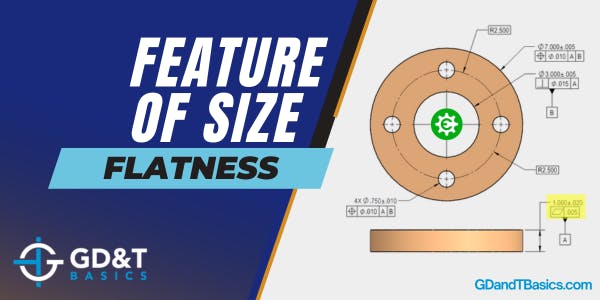

In this Question Line video, Jason compares flatness directly applied to a surface associated with a feature of size against flatness applied to a feature of size.

In this Question Line video, Jason explains how to calculate the flatness tolerance of a surface for a given example based on the size tolerances and Rule #1.

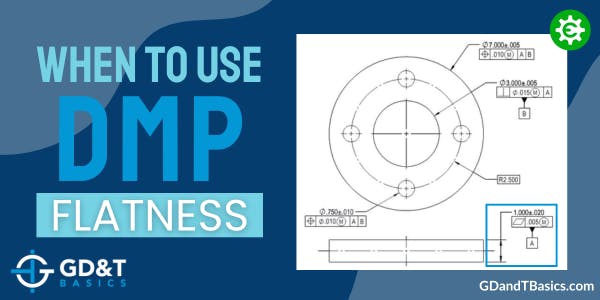

In this Question Line video, Brandon explains the application of derived median plane (DMP) Flatness and discusses its frequent misuse and potential issues when used for stacking parts. He also provides an alternative for controlling flatness for stacking or symmetrical parts.

In this Question Line video, Jason answers questions regarding datum targets and applying flatness and profile of a surface.

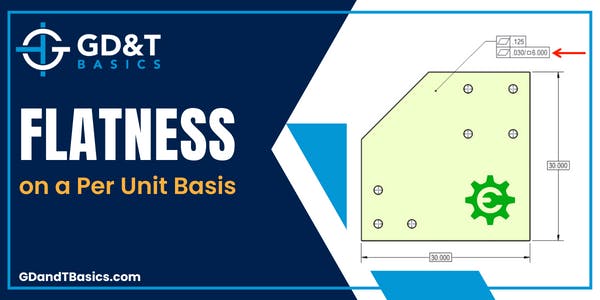

Jason discusses form controls on a per unit basis using the example of controlling flatness on a large surface in this Question Line Video.

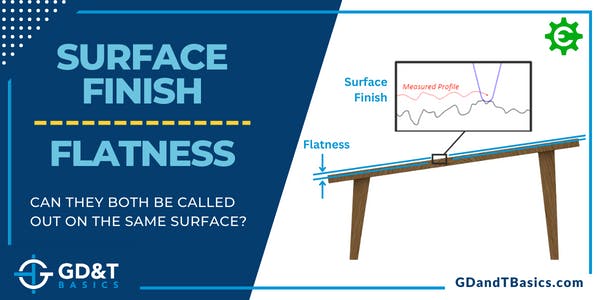

Surface finish and flatness both limit the amount of variation in a surface – one at the micro level and one at the macro level. Is it permissible to call out both on the same surface?

Check out this question brought up about Flatness in our GD&T Fundamentals Course. We get a lot of questions about when flatness can be applied and how datums can be used with this. There are...

GD&T Flatness is a common symbol that references how flat a surface is regardless of any other datum’s or features. It comes in useful if a feature is to be defined on a drawing that needs to be uniformly flat without tightening any other dimensions on the drawing. The flatness tolerance references two parallel planes (parallel to the surface that it is called out on) that define a zone where the entire reference surface must lie.