What is Knurling?

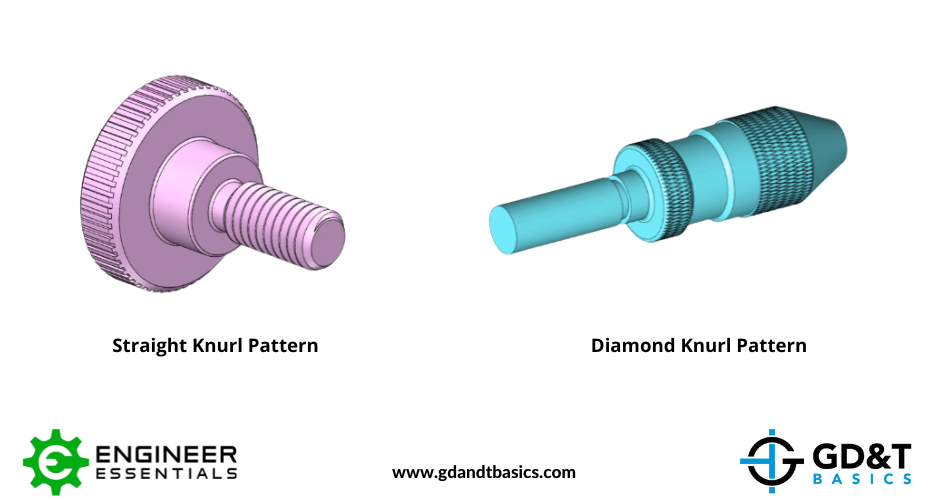

Knurling is a process used to create a pattern on the surface of a material by displacing or deforming the surface. Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. Three common knurl patterns are: straight, diagonal (left or right-hand), and diamond.

Knurling Applications

Knurling can serve both functional and decorative purposes.

Ergonomic knurls, frequently applied to improve grip, also give a decorative texture to a surface. You will commonly see these knurls on tool handles, such as ratchets and hammers. Many other household items, such as barbells, nutcrackers, and cabinet pulls may also be knurled.

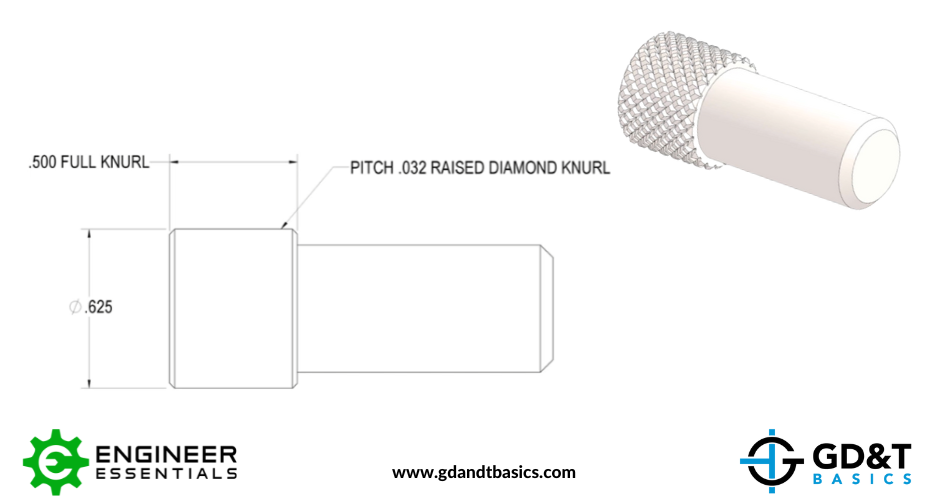

For an ergonomic or decorative knurl, the following information should be included on the drawing:

- Knurl type (straight, diamond, left or right-handed, etc.)

- Pitch (the distance between the knurl elements)

- Diameter prior to knurling

- Location and length of knurl, if only a portion of the part is to be knurled

Drawing Example for an Ergonomic or Decorative Knurl

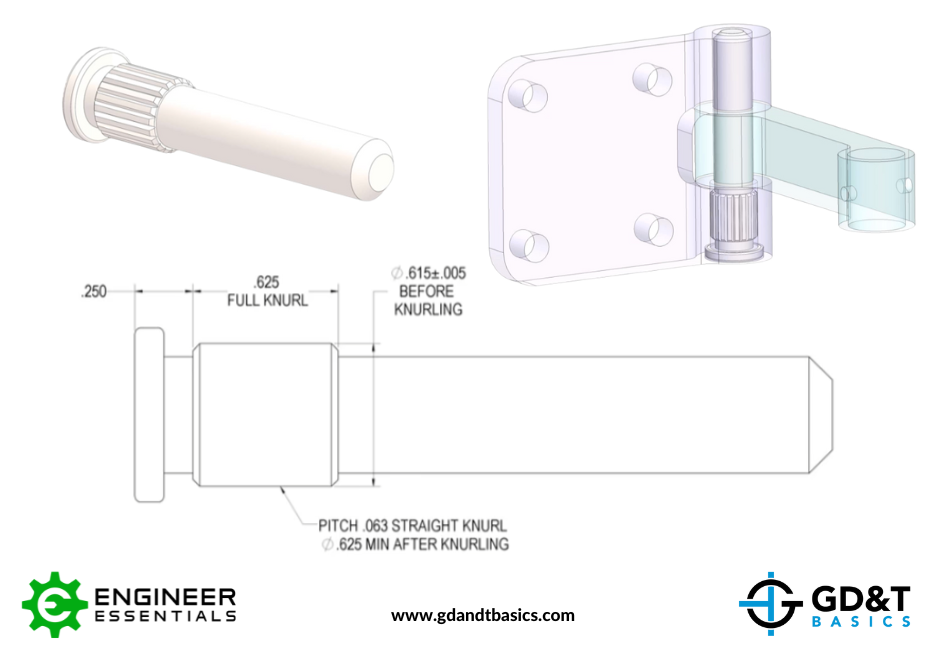

Knurling is also used for press-fit applications. When indicating a press-fit knurl on a drawing, the drawing must additionally include the toleranced diameter of the feature before knurling, and the minimum acceptable diameter of the feature after knurling (which determines how much press fit force there will be).

Drawing Example for Knurl used in a Press-Fit Application

For more information, watch our video explanation of knurling, below:

Be The Go-To Engineer at Your Company

Learn Print Reading and GD&T at your own pace and apply it with confidence in the real world.

Get Print Reading Training