The most common way to produce an internal thread is to drill a hole and then use a tap to produce the thread. This is usually referred to as a tapping drill for the size of the thread that needs to be produced.

There are rules of thumb that you can use to calculate the tap drill size you need. You can also determine your tap drill size by digging into the Machinery’s Handbook, where you will find all of the different classes of threads listed. To make your search easier, we have created our own Drill Tap Chart that includes only the information that you would most commonly need to properly drill and tap holes. To create our chart, we pulled the basic numbers for the most common threads, class 2B, from the Machinery’s Handbook. A link to download our handy Drill Tap chart is located at the bottom of this article.

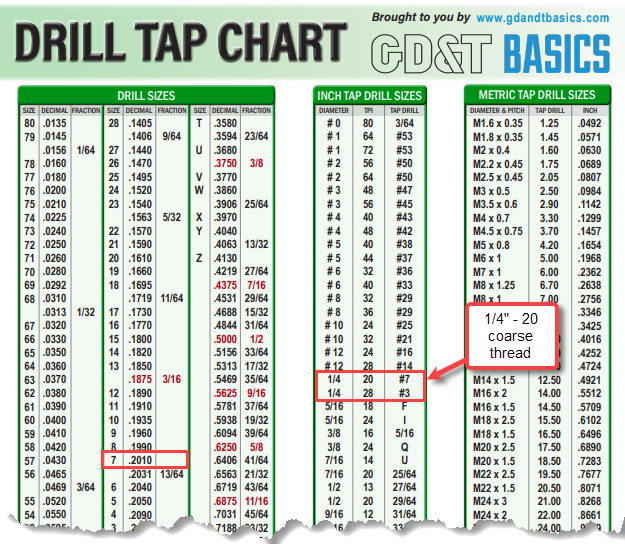

Our Drill Tap chart includes values for screw sizes and the proper size drill bit to use to make the hole for the tap. We have included four unique tables on our chart:

- DRILL SIZES – This table lists all drill sizes up to 1.000” and the most common from 1.000” up to 1.500”

- INCH TAP DRILL SIZES – This table lists the most common tap sizes, typically one coarse and one fine thread for each size, from a #0 to 1-1/2”

- METRIC TAP DRILL SIZES – This table lists the most common tap sizes, typically one coarse and one fine thread each, from M1.6 to M39

- PIPE THREADS (NPT) – This table lists the common NPT threads from 1/16” to 3”

How to Use our Drill Tap Chart

Let’s look at an example to demonstrate how to use our chart. Say that your drawing has a 1/4” thread call out. To determine what tap drill size you need, go to the “Inch Tap Drill Sizes” table in our Drill Tap Chart. (See Figure 1.) In the left-hand column of the table, you will see two 1/4” options. The first option, 1/4″-20 is the coarse thread option (fewer threads per inch). The 1/4″-28 is the fine thread option. The Machinery’s Handbook tells us that as a best practice, you should always default to the coarse thread first, unless there is a reason that you need a fine thread. After finding the 1/4″-20 thread in the Inch Tap Drill Sizes table, we would slide over to the right-hand column of that row and discover that we need to use a #7 Tap Drill. If we then look at the “Drill Sizes” chart, we see that a #7 drill has a size of 0.201”.

If your drawing contains a metric thread callout, you would go to the “Metric Tap Drill Sizes” table and follow this same procedure. When there are two entries for a thread diameter, the coarse thread is always listed above the fine thread.

Considerations for using our chart:

These tap drill diameters provide approximately 75% of a full thread to be produced. (75% of actual thread form, not depth of thread.) These values come directly from the Machinery’s Handbook.

Consideration must be given for class of thread, harder materials, machine and tool holder used, condition of drill, etc. Our chart gives the values for the most common thread type used – class 2B. Consult the Machinery’s Handbook if a different thread class is required.

For a more in-depth discussion of thread terminology, rules of thumb, design tips, and most importantly, how to use our chart, check out the video below.

Looking for a handy chart to help you drill and tap holes?

Download our FREE Drill Tap wall chart today!

DOWNLOAD FREE WALL CHART