Symbol: CR

Definition:

The Controlled Radius is a variation of Radius. It dimensions the size of a circular feature using the radius length, but it also gives an additional requirement – that the surface of the contour must be a “fair” curve. This means that the surface must be continuous, without reversals.

Application:

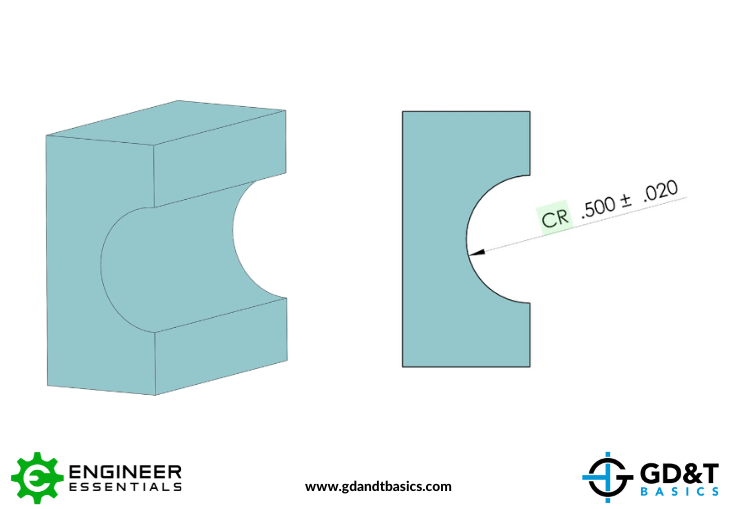

When a Controlled Radius is required, the symbol “CR” is placed before the size dimension, as shown below in Figure 1.

Figure 1: Circular Feature with Controlled Radius Dimension

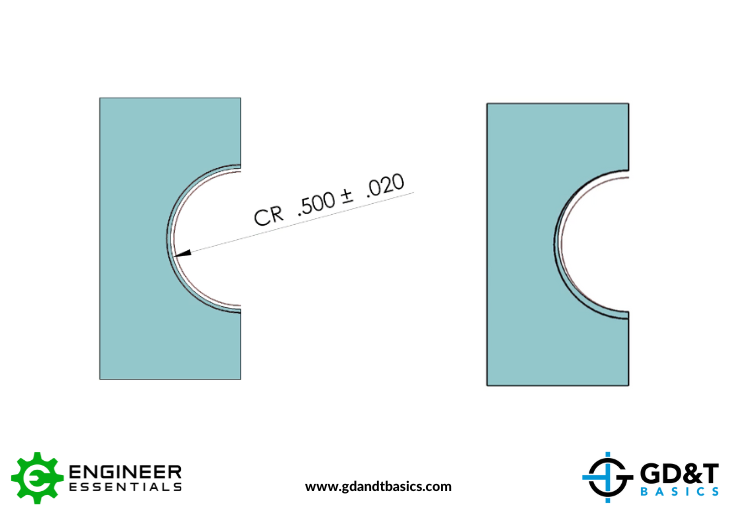

The difference between a Radius and a Controlled Radius is in the contour of the machined feature. While points along the “Radius” dimensioned surface must only fall within the tolerance zone, points along a “Controlled Radius” surface must fall within the tolerance zone AND be a continuous arc, as shown in Figure 2.

Figure 2: Machined “Controlled Radius” within Tolerance Zone

The requirement for a Controlled Radius may be common on critical bore surfaces or bearing surfaces. When machining, a Controlled Radius is achieved by slowing down the machine’s feed rate to prevent reversals.

Stop hunting through pages. Get our GD&T Symbols Chart—your quick reference guide with every symbol on one page.

Save it to your desktop or print it out for quick reference. We’ll send the digital chart straight to your inbox. No spam, just helpful GD&T resources.

Get Your Free Chart